In any engine, the crankshaft is undeniably one of, if not the, most important components. As such, when it comes to regrinding a crankshaft only a trained specialist should be trusted. Read on to learn more about the engine crankshaft, including how often it needs regrinding, and exploring just how critical it is that a specialist be the one to do the job.

Crankshaft regrinding is a process in which a damaged or worn crankpin or main bearing journal diameter, is ground to the smaller size to restore geometrical tolerances and suit a new oversize bearing shell. This is done in order to try and preserve and lengthen the lifespan of the crankshaft, as it is a vital, yet possibly expensive, part of the engine. Typically speaking, there is no set timeframe for when a crankshaft should be reground. However, it's an action that is usually done when rebuilding an engine, to ensure that it is working at an optimal level of accuracy.

- the journal of the crankshaft is no longer square.

- the surface of the journal is worn down, meaning it no longer meets the tight geometric tolerances specified by the OEM.

- the journal is damaged due to failure.

Often, a crankshaft will become damaged if there is insufficient lubrication, if there is an over-pressurised cylinder, or if there is a coolant leak.

Correctly grinding a crankshaft requires a whole depth of specialist knowledge, as well as detailed insight into crankshaft turning, and the ability to troubleshoot any potential issues before they arise. Even prior to being reground, the crankshaft must be thoroughly inspected for damage and cleaned of any oil and residue build-up. While it's true anyone could spot the large tell-tale signs of wear, only a specialist knows what to look for when it comes to scoping out minuscule damage.

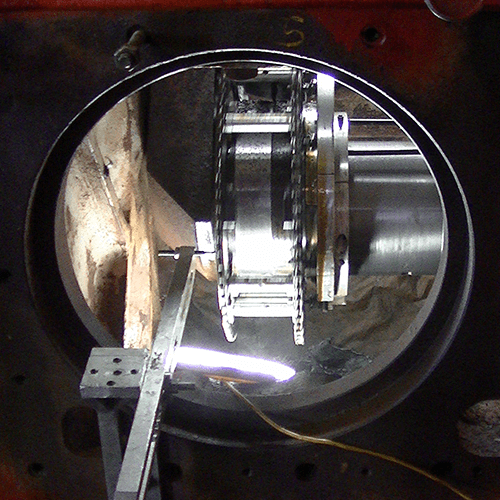

When it comes to the regrinding itself, an impeccably high level of accuracy is required. Only a specialist has the trained eye to do this. If the grounding is done incorrectly then the crankshaft may be damaged further - resulting in further costs of crankshaft repair - or else put out of service entirely. Regrinding the crankshaft is also a highly technical process and requires a complicated piece of equipment, of which incorrect use can result in injury.

In-Situ offers both an on-site machining service and portable machining services. From line boring services to crankshaft turning and crankpin machining, we offer a broad range for clients to choose from. Not only this but, thanks to our 24-hour emergency machining response, you can be seen to and fixed as soon as possible.