In-situ Machining Solutions (UK) Ltd have recently completed a major on board machining and metal stitching repair programme to a 9 cylinder main drive diesel engine for a South American navy after a major failure resulting in one of the 400mm diameter pistons being ejected from the engine and balance weight detachment causing extensive damage to major components of the engine.

As the replacement of major engine parts listed below were not readily available, the work was undertaken by In-situ Machining Solutions (UK) Ltd at the request of a leading diesel engine manufacturer and involved the refurbishment of one of the crankshaft’s large end crankpin journals together with extensive repairs to the cast iron cylinder block and bedplate which had been severely damaged and broken into several pieces due to the impact of the engine failure.

To enable the repair work to be conducted, an initial survey had taken place by the OEM followed by In-situ personnel to establish what parts were required to affect the repair work in the most effective and efficient way. Having done this, In-situ had to design and produce several new casting inserts and transport these and all the necessary machines and tooling to South America.

Prior to the work commencing, the cylinder block had to be lifted off the bedplate by approximately one metre to allow access with repair machinery enabling the remedial work to take place.

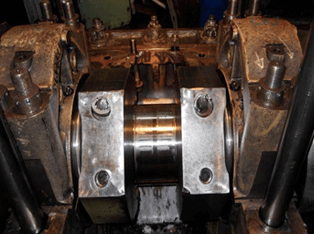

Crankshaft Work

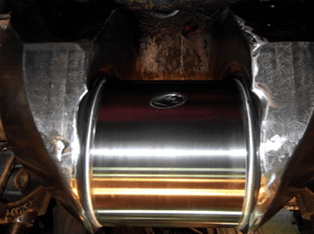

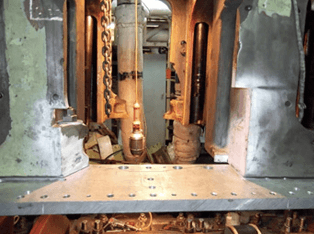

Crankpin- the 300mm crankpin had to be reduced in size as a result of impact indentations. 3mm had to machined to remove all damage using one of the company’s specialist on site orbital or planetary portable machining equipment and associated superfinishing and polishing tooling. 3mm undersize bearings were provided by the manufacturer to compensate for the reduction in the crankpin size.

The crankpin was refurbished to the OEM specification in terms of geometric size, roundness, flatness and surface finish. On completion of the work a physical check to establish crankshaft bend using a dial indication system proved that after repair to the crankshaft was within the OEM tolerance for crankshaft straightness.

Balance Weight Location

Four studs which secure the balance weight to the crankshaft had sheered at the joint face of crankshaft, these were carefully drilled and extracted with no further work having to be done in this area.

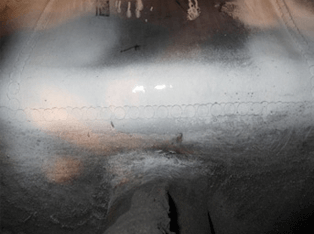

Bedplate Sump Work – Exhaust Side

Impact damage to the bedplate took the form of an indentation 230 x 230mm x 30 mm thick breaking through the exhaust side of the bedplate leading to the distortion of the bedplate to it’s mating cylinder block leaving a gap of up to 5mm between the two components.

To overcome this problem of impact damage and adjacent cracking, the offending damage had to be completely cut out leaving an aperture through the bedplate base of 320 x 320mm.

In-situ Machining Solutions (UK) Ltd. produced a cast iron make-up piece to fit the dimensions of the cut-out, tapped it in place, and using a series specialised metal stitching pins and locks, secured the make-up piece in place. This process together with a sealing agent ensured an extremely strong and leak free repair.

Bedplate Joint Face – Exhaust Side

Damage to two bolt holes were repaired by cutting out and fitting new inserts which were stitched, locked and sealed in place. New holes were drilled and spotfaced into newly fitted inserts to design sizes. An allowance of 2mm had been left on the inserts to allow for a final machining operation to blend the newly fitted parts into the adjacent parent joint face of the bedplate.

Bedplate Joint Face – Camshaft Side

A 50mm long fracture was repaired using stitching pins and locks and hand dressed to blend in with the existing joint face.

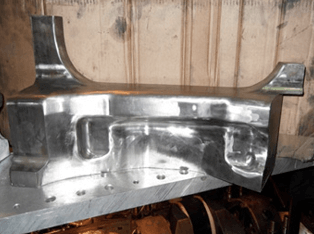

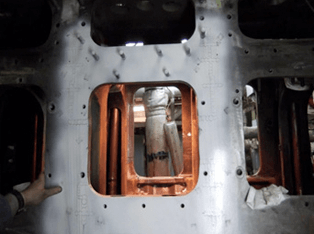

Cylinder Block Repair – Exhaust Side

Due to the detachment of the balance weight and its’ penetrating the crankshaft access door/window, an extensive repair was undertaken to repair the damaged window frame. The bottom ledge of the widow adjacent to bedplate joint face had been completely shattered. Prior to fitting a new section of widow, designed and produced by In-situ Machining Solutions (UK) Ltd, the broken and jagged areas of the break had to be tidied up by means of a precision portable milling machining exercise. Once machined new insert was carefully fitted into the newly machined aperture and duly stitched, locked and sealed using a series of toughened, technically advanced stitching pins, hardened locks and sealant.

An allowance of 2mm had been left on the window and joint faces of the new insert to allow a final machining operation to blend these surfaces with the existing parent window and joint faces.

Four holes, used for securing the cylinder block to the bedplate were drilled and spotfaced to design size and positioning. So too the tapped holes in the vertical face of the window to enable the fitting of a new access door.

Cylinder Block – Camshaft Side

The repair to this side of the engine was very similar to that of the exhaust side of the engine with the addition of breakage to the camshaft access window. A new inert was fitted to the lower sill of the crankshaft window with the addition of a new section fitted, secured and machined to the camshaft access window.

All machining, drilling and tapping work was as conducted to the exhaust side of the cylinder block.

Camshaft Bore Alignment

As a precaution, the camshaft bore line was checked for alignment to measure if any possible distortion had taken place as a result of the engine failure. No alignment problems or bore size had been affected and were within OEM tolerances. This aspect of the work was conducted using an optical alignment system and calibrated bore measuring equipment.

All work was completed to the satisfaction of both, the OEM and the naval personnel.

Carrying out this work on board saves totally dismantling the engine, cutting massive holes in the ship to enable extraction of the engine and transporting to a factory for refurbishment. It also gives control to the end user as the work is being executed, in this case on a naval vessel, where the client can see exactly what is going on and on progress being made.

The following photographs give an indication of the extensive repair work being carried out.