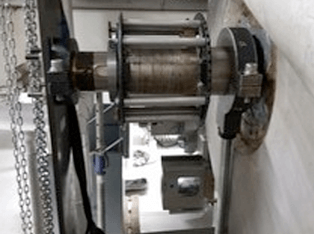

In-Situ Machining Solutions (UK) Ltd were contracted in for the on-site machining repair of a damaged Stainless Steel mixer blade shaft in France during a Christmas shutdown period. After sustaining damage to a SS316 giant 150mm outside diameter mixer blade shaft during operation, our client decided to utilise the Christmas shutdown period to implement a pre determined on-site repair process.

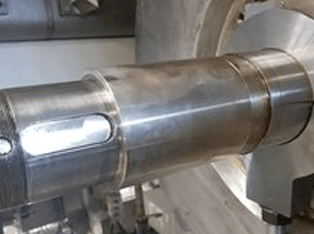

The client wanted In-Situ Machining to provide an engineered solution for the restoration of the shaft back to original dimensions. After much communication with the technical team at In-Situ Machining, a proposal was made to the client and it was decided that the best solution to the problem would be to machine the shaft and ‘sweat’ a make-up sleeve over the machined shaft with a small interference fit. The sleeve would then be finish machined to design size following the above operation. Prior to the start of the project, In-Situ Machining manufactured two off Stainless Steel make-up sleeves during the preparation period for the job.

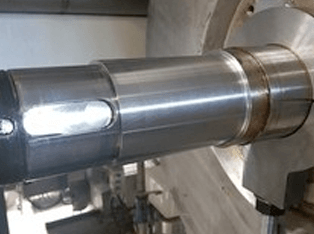

Once the plant had shut down for Christmas, In-Situ Machining attended site and began tight tolerance machining of the shaft diameter to remove the existing damage and size the shaft for the fitment of the 0.10mm – 0.15mm interference fit, pre-manufactured sleeve. During this time as the 2nd mixer blade was being stripped out it was found that this had also sustained similar damage. In-Situ Machining immediately responded by supplying an additional team to operate on a 24 hour shift pattern as the quantity of work had doubled yet the timeframe for completion could not slip. Both shafts were machined over the complete 220mm length and sleeves ‘sweated’ on ready for the final machining process to begin. The final machining, superfinishing and polishing operation began to hit the tight tolerance applied to the finishing of the shaft bearing diameter. A size tolerance of 0.03mm, taper & ovality tolerance of 0.02mm and a flatness (straight edge and engineers blue Ink technique) tolerance of over 95% were all achieved on both shafts within the shutdown timeframe that was allocated to the work scope.

The client was not only impressed by the engineered solution proposed by In-Situ Machining but also the flexibility and workmanship shown by the teams deployed whilst working to tight tolerances and against the clock.