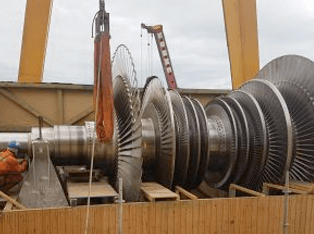

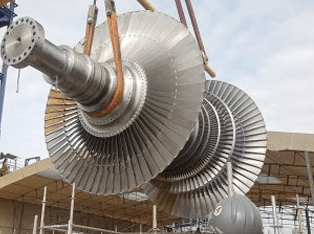

At a brand new power station in South America, personnel discovered whilst opening a packing case containing a new 80 tonne LP Turbine Shaft, that the J Shape Labyrinth Seals had been severely damaged and would require replacing and re-machining to OEM specification.

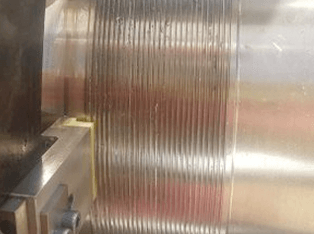

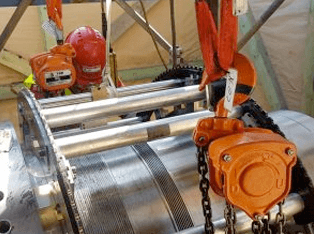

The In-Situ Machining design team made special tooling to successfully complete this project, as the stainless steel J Shape Labyrinth Seals were only 0.35mm thick and required 5mm machining off the 900mm diameter to a tolerance of 0.1mm on diameter and a concentricity tolerance of 0.025mm. Inspection was passed off by the OEM and the power station personnel.

In-Situ Machining completed this within the limited time allocated so that the build schedule was not affected.

Obviously if the shaft had been returned to the manufacturer’s workshop this would have entailed a delay of several months.