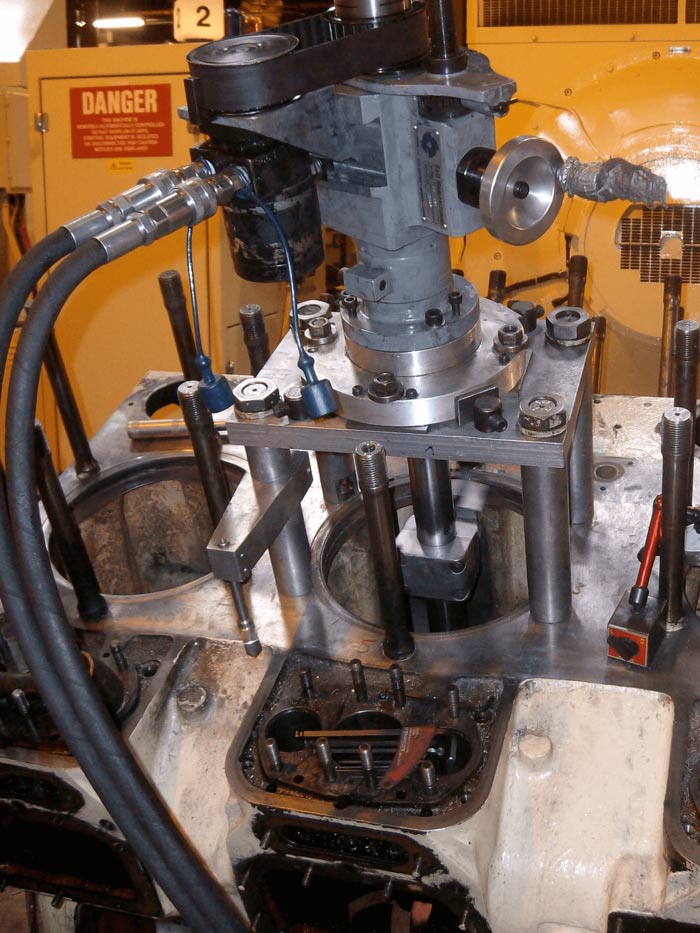

Extreme wear and damage to Upper and Lower landing seal areas of large generators, diesel/gas engines and compressors can mean costly replacement and downtime. Over many years, In-Situ has designed, developed and perfected a specialised boring and facing system as part of our on-site machining services to allow asset owners an alternate solution to replacement components.

In-Situ Machining Solutions (UK) Ltd have the expertise to repair damage to the areas of the cylinder blocks caused by engine failure, severe wear or fretting corrosion to give 'as new' repair results. With multiple repair options, including make-up sleeves and rings, inserted with interference fits, thermal spraying and selective plating, In-Situ has a solution to suit all engine types.

If the cylinder leaks water into the crank bays, with inevitable damage to the crankshaft and mating parts, In-Situ is ideally placed to assist with all associated crankshaft repairs. For example, if broken pieces or fractures occur in these seal areas, our advanced stitching system can be employed to rectify the problem. In conjunction with the make-up sleeve, the insertion procedure has proved invaluable and a cost-effective repair solution for OEMs and equipment owners.

Extreme wear or damage to a large generator's upper and lower landing seal areas within diesel or gas engines and compressors will mean costly replacement and downtime.

Proper liner landing machining is crucial for the performance and longevity of an engine. The landing surfaces of cylinder liners must be machined to exact tolerances to ensure the piston rings can form a proper seal and minimise oil consumption. It also prevents excessive oil consumption, improving fuel efficiency and reducing emissions. Proper liner landing machining also contributes to the overall reliability and longevity of the engine.

Over many years, In-Situ has designed, developed and perfected a specialised boring and facing system to allow asset owners an alternate solution to replacement components.

Our bespoke equipment includes boring bars, cutters, reamers and honing machines that can all be transported to your location for the machining services.

Our expert engineers, equipped with our specialised tools and equipment, will follow a precise but versatile range of processes to achieve consistent and accurate results and, as a result, not only repair the damage but improve the performance of the engine long-term.