Industrial facilities rely on their machinery to operate at its best every day, but this constant use under extreme conditions will expose these valuable assets to many different forms of damage or wear, including crankpin ridge wear. Read on to discover the dangers of this form of wear and how we solve it for companies globally.

Crankpin ridge wear is a common problem affecting the connecting rod bearings and crankpin journals of internal combustion engines. This is especially common for the industrial engines that our team repairs; their extended operation will make them more susceptible to wear over time.

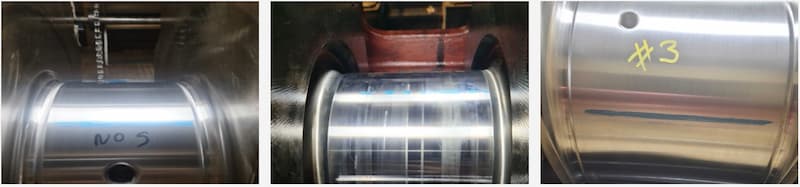

Specifically, it relates to the wear on the surface of the crankpin, which is part of the crankshaft. As the engine runs and the crankshaft rotates during operation, friction between the crankpin and the connecting rod bearing causes the material to wear away from both surfaces. When this wear becomes excessive, it can lead to a ridge forming in the centre of the crankpin and more prominent on bottom dead centre of the journal, which will cause significant damage to the connecting rod bearing and other engine components if left and not repaired.

This form of engine wear will not only affect the crankpin and create potential downtime as it needs repairs, but when ignored, ridge wear will cause additional, long-term damage to your engine. When the ridge on the crankpin becomes excessive, it contacts the connecting rod bearing, leading to metal-to-metal contact and increased friction, which generates heat and can cause the bearing to break down and damage the crankpin journal. If the engine is left to run for only a few minutes when the component get to this stage, it can result in significant damage to the engine and may require costly repairs or worse, replacement. Additionally, the ridge on the crankpin can cause metal particles to break away and circulate through the engine oil, causing further damage to other engine components.

Decreased performance, increased noise and vibration, and even catastrophic engine failure are all likely if the issue is not addressed. Therefore, it's crucial to monitor and manage any signs of crankpin ridge wear as soon as possible so a trained team like ours can be brought in to fix it as part of your preventative maintenance and ensure the longevity and reliability of the engine. In addition, regular maintenance and inspections can help prevent the development of crankpin ridge wear and minimise the risk of engine failure. Additionally, our on-site machining services will reduce the already minimal downtime even further.

Crankpin ridge wear repair is an effective solution to this common problem in marine engines, and it can have severe consequences if not addressed promptly. The connecting rod bearings in marine engines are subjected to harsh conditions, high loads, and extended periods of use. These conditions can accelerate wear and tear on bearings and crankpin journals and cause the development of a ridge on the crankpin.

Regular maintenance and inspections are crucial to prevent crankpin ridge wear in marine engines. This includes checking the oil and oil filter for signs of impurities & metal debris, monitoring engine performance, and inspecting the connecting rod bearings for wear and damage.

If crankpin ridge wear is detected, promptly addressing the issue is essential. Our team of expert engineers will arrive on-site with our bespoke modular equipment to conduct the required marine repair operations as needed. This may involve replacing the connecting rod bearings, grinding down the ridge on the crankpin, or even replacing the entire engine in severe cases. Failure to address crankpin ridge wear can lead to significant engine damage and costly repairs or replacement, which can be avoided with proper maintenance and attention to the warning signs of crankpin ridge wear in marine engines.

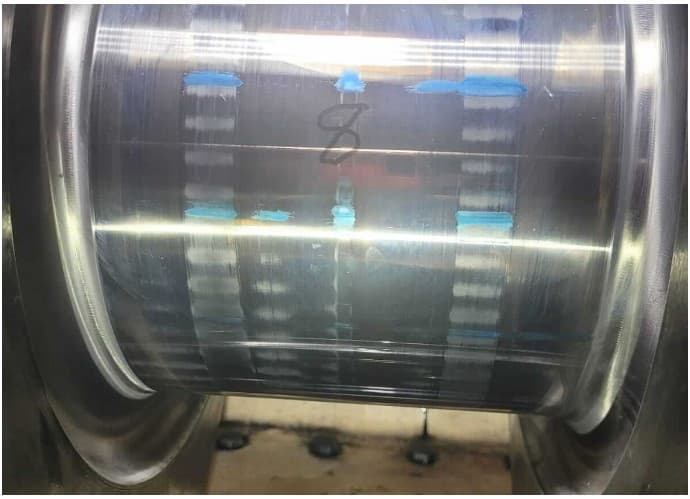

Repairing methods for industrial crankpin ridge wear can be more complex and time-consuming due to the size and power of industrial engines, creating extended downtime and significant expenses to have the engine repaired offsite. Fortunately, we offer an on-site machining service that will repair the engine at your location and reduce lost time and cost. Here are some common repair methods for industrial crankpin ridge wear:

Polishing the ridge – If Ridge wear is determined at an early stage, this repair method involves carefully Machine polishing of the ridge on the crankpin journal to dress to the current size of the crankpin journal and restore flatness. This avoids machining to the first undersize bearing.

Machining down the ridge - This repair method involves machining the crankpin journal to suit the first undersize bearing.

Replacing the crankshaft - In severe cases of crankpin ridge wear, where the ridge is too large to be ground down or the crankshaft has been damaged, the crankshaft may need to be replaced entirely. This requires removing the engine from the equipment and disassembling it to replace the crankshaft.

At In-Situ Machining Solutions, we have a great deal of expertise in conducting crankpin machining for various industrial applications, including:

Our global on-site machining services are highly effective for resolving many wear and tear issues successfully. Contact us to discover how our expert engineers, with their high-quality, modular repair tools, will help you maintain your deadlines and not be delayed by crankpin machine wear.