We know the severe implications machinery failures bring to the power generation industry. Machinery failures may seemingly present themselves as small issues until they generate a chain reaction of undesirable outcomes such as unplanned downtime, loss of production, and excessive repair costs. Read on to discover what our expert engineers help power generation facilities avoid and how with our range of portable machine repair services.

Unplanned downtime is inarguably one of the immediate consequences of machinery failure in any industry. These unexpected shutdowns disrupt the regular flow of operations, simultaneously hindering productivity and profitability. For us as service providers, efficiency is paramount, and any disruption directly challenges this goal.

The resultant loss of production waiting for power generation machine repair has a direct financial impact. Every moment a generator or turbine stands idle equates to lost revenue. Compounded over extended periods, these losses will be vast, necessitating quick and proficient intervention to combat these periods.

The repair costs associated with machinery failure are not insignificant. Transporting damaged components to a repair facility isn’t simply costly; it also further extends downtime. As specialists in on-site repairs, we aim to help diminish both these costs and the associated downtime.

Beyond the direct impact on the power generation industry, machinery failures also extend into the broader economy and public safety of the associated area. The economy relies heavily on power supply. A power-less factory halts production; a power-less business can’t operate; a power-less hospital can’t treat patients. It is this relatability that highlights the crucial role continuous power supply plays in our daily lives and the economy at large.

Any moment that a machine is rendered unproductive due to a failure equates to a loss for the facility. However, with on-site machining repairs, these downtimes can be significantly curtailed. Rather than shipping off machinery components to be repaired off-site, which exerts a taxing cost in terms of time, money, and logistics, we champion a more efficient approach at In-Situ Machining Solutions.

Our on-site repair services, such as the ones listed below, ensure that the faulty motion of your machinery is halted for the least possible time:

The on-site (or in-situ) capabilities of our engineers not only allow us to conduct necessary repairs briskly but also enable us to consider the broader context of machine operation, such as how other components are affected and what else can be done. At the same time, the machinery is paused to avoid future downtime. By doing so, we can limit the need for extensive machine dismantling and help get the operation up and running sooner than traditional repair methods might allow.

Our teams are as equally committed to ensuring the safety of the workforce, facility, and environment as you are. On-site repair services have an inherent advantage in this area, as our engineers are fully prepared to comply with your site safety procedures. Thus, the risk of accidents or further damage to the machinery during transportation is virtually eliminated.

Effective site management is instrumental in maintaining operational efficiency and safety standards. Our experienced teams are adept at blending seamlessly into your operations, ensuring that all work is carried out to the highest safety protocols. Our robust preparation process and extensive communications mean that we can accurately tailor our services to suit the specific safety needs of your plant.

We don’t just assist legacy power generation, but we are capable of assisting new renewable power generation with renewable turbine repair.

With the rise of the UK's green economy and the UK Net Zero 2050 plan, there's an increased focus on enhancing the number and effectiveness of renewable energy sources. Large-scale wind, wave and solar farms are sprouting, boasting an impressive production of about 11.6GW (gigawatts) of electricity. Yet, just like their non-renewable counterparts, these renewable energy generation sites require regular maintenance and repairs.

We've noticed that renewable energy, much like any other power generation, hinges on predictable machinery that needs to function dependably. Yet, unexpected downtime remains a pressing concern for any energy-generation facility, making preventative in-situ maintenance absolutely critical to operations.

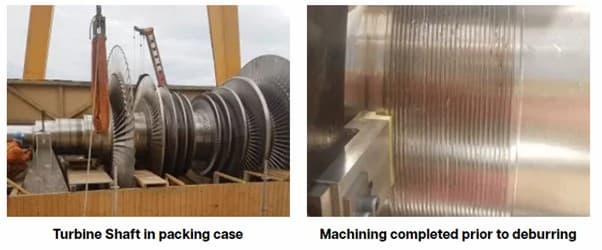

Embarking on a new turbine machining project at a power station in South America, our team at In-Situ Machining Solutions immediately faced a challenge. Damage was detected to the J-Shape Labyrinth Seals on a newly unboxed 80-tonne LP Turbine Shaft. The damage called for instant repair and meticulous re-machining to the original manufacturer's specifications. Failure to intervene instantly and with precision would expose the power station to dire operational hindrances.

We pride ourselves on our quick-thinking and flexible approach. To address this pressing issue, our design department promptly put their expertise to work, creating tailor-made tools suited to the task. The complexity of the task wasn’t insignificant. The J-Shape Labyrinth Seals, composed of stainless steel and a mere 0.35mm thick, necessitated shaving off a precise 5mm from the 900mm diameter. The tolerances were equally intricate, with 0.01mm in diameter and a concentricity tolerance of 0.0025mm. This task was not just about applying technical knowledge; it was an exercise in precision and attention to detail.

Choosing a reliable repair team fortifies your faith in your station's maintenance capabilities and resilience. Working with In Situ Machining Solutions, you’ll have the power generation repair you need when you need it so you can maintain your current capacity to deliver steady energy output for essential networks or machinery.

We stand by the excellence of our services, confident we'll fulfil your expectations. Contact us today to address your repair requirements and directly reap the rewards of our proficiency.