In essential sectors such as power stations, swift and efficient machine repair services are a must-have. With the right team and equipment, the downtime required is reduced to minimal levels and power station productivity is largely ensured.

We pride ourselves on our ability to fulfil these requirements consistently with our on-site machining services. Our team provides punctual, effective machine repair solutions that minimise operational disruption and maximise production. Our engineers, expertly trained and experienced, deliver top-notch repair services with their mobile, bespoke equipment and provide long-lasting results that have earned us client trust and industry respect.

The following is a selection of summarised case studies involving our team travelling internationally to solve various power station repair challenges. Read on to see examples of their expertise for yourself.

Our team were tasked with rectifying severe pitting and corrosion damage on two offshore compressor crankshafts. Their unusual design and the pressing need for repair posed a unique challenge, as on-site visits for data collection were not possible.

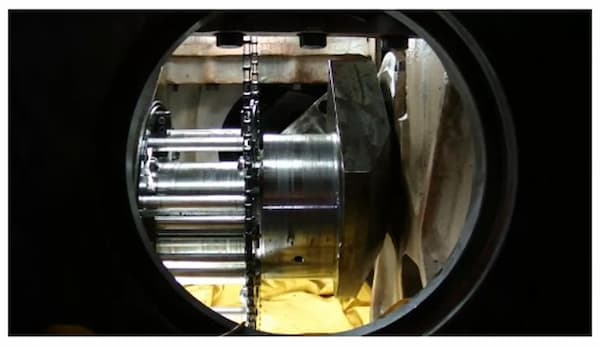

This required orbital machining, so we manufactured bespoke equipment for our orbital turning machines, ensuring they fit the offset journals. The plan was to turn each crank diameter to the first undersize bearing - 116 below the norm. The entire shaft refurbishment was planned over two phases, with the crew operating round-the-clock.

In spite of the challenge, we finished ahead of time, enabling additional repair work. Our client appreciated our efficient completion of both crankshafts, demonstrating that our team is prepared to handle intricate, time-critical missions successfully.

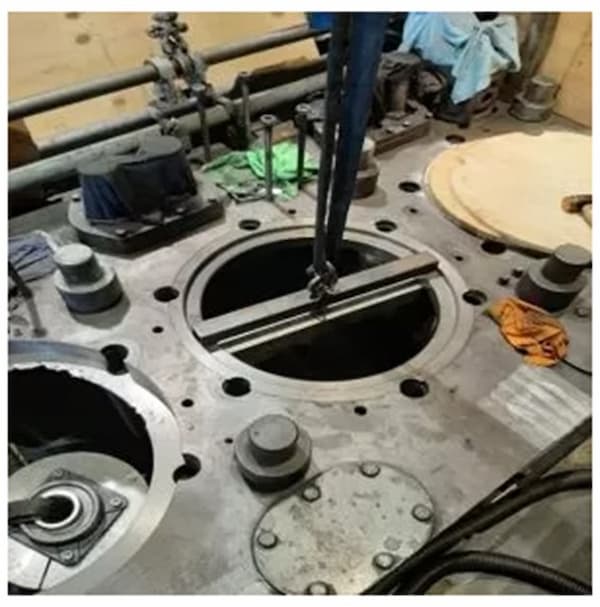

In this example, we tackled severe cracking in an HV power station's engine block in the Caribbean. This challenge was amplified due to the client's inability to procure a new engine block, turning our repair work into the only viable solution.

We initiated the repair with an in-depth damage survey that revealed extensive cracking around the liner landing and cylinder head threaded stud holes. The final work scope involved removing all the existing damage by machining the cylinder liner land area to a diameter of 650mm and inserting a specially manufactured SG Iron insert.

To combat further cracking, we implemented cold metal stitching, sealing the new insert into the machined engine block. The additional process of refurbishing the thread holes with an M64 x 3mm thread markedly reduced the risk of future cracking. Our diligent machining work and reinforcement techniques resulted in a reliable block face, perfect for reassembly. Even the lower liner landing area was bored out to fit a new steel insert repair sleeve, which further bolstered the structural integrity of the engine block.

More than a year later, the engine continues to run smoothly with no recurrence of cracking. This on-site repair not only saved a substantial amount for the client but also ensured continuous power supply in the region, thus making a significant contribution towards preventing energy shortages. This case illustrates how we at In-Situ turn 'scrap' into 'salvage' through our expertise in metal stitching and dedication to innovative repair solutions.

At a newly built power station in South America, our team was faced with an unexpected situation. Personnel discovered severe damage to the J Shape Labyrinth Seals of a newly unpacked 80-tonne LP Turbine Shaft. Without repair and precise re-machining to the OEM specifications, the power station was in danger of incurring severe operational challenges.

To address the difficulty, our design team swiftly created specialised tools. The stainless steel J Shape Labyrinth Seals, merely 0.35mm thick, required a precision machining down by 5mm off the 900mm diameter with a tolerance of 0.01mm on diameter and a concentricity tolerance of 0.0025mm. This called for absolute precision and attention to detail. Through our expertise and precision, we completed the project within the given time frame, leaving the station's build schedule unaffected. Had the shaft been returned to the manufacturers for repairs, it would have caused a delay of several months.

At a manufacturing plant in the UK, we were re-engaged to address recurring issues in 635mm OD Slip Rings on a rotor. This came a decade after our team handled the same task, which resulted in a successful outcome for the client. A survey revealed the similarities between the previously replaced shaft and the current one. Even though there were surface damage issues to address, with the brush and slip-ring surface on the new shaft, we leveraged our extensive experience and engineered a precise repair plan.

The required flexibility was exhibited to meet the client's shutdown schedule, executing the project over four shifts in a round-the-clock working pattern. Each ring was delicately machined to remove minimum stock, ensuring a clean, damage-free surface that complied with OEM's requirements. Presently, the rotor is operational, with weekly checks affirming the success of the repair. All components show signs of efficient operations, demonstrating our continuous dedication to providing effective, long-lasting solutions to our clients.

Choosing a reliable team will build confidence in your station's maintenance and repair functionality. As a result, this reliability will underscore your station's ability to provide consistent power output to where it's needed, be it a power grid or facility machinery. We are confident that our services will meet and exceed your expectations. Contact us today to discuss your repair needs and benefit from our expertise yourself.