Crankshafts are an essential part of any engine. Whilst most people are familiar with these parts in car engines, they are also prevalent in larger industrial applications. Many sectors rely on industrial crankshafts within their onsite engines to conduct daily operations. Consequently, industrial crankshafts must be kept in peak condition like any other machine component to maintain peak productivity and eliminate costly downtime. This blog discusses industrial crankshafts, their applications, and why regular maintenance is vital.

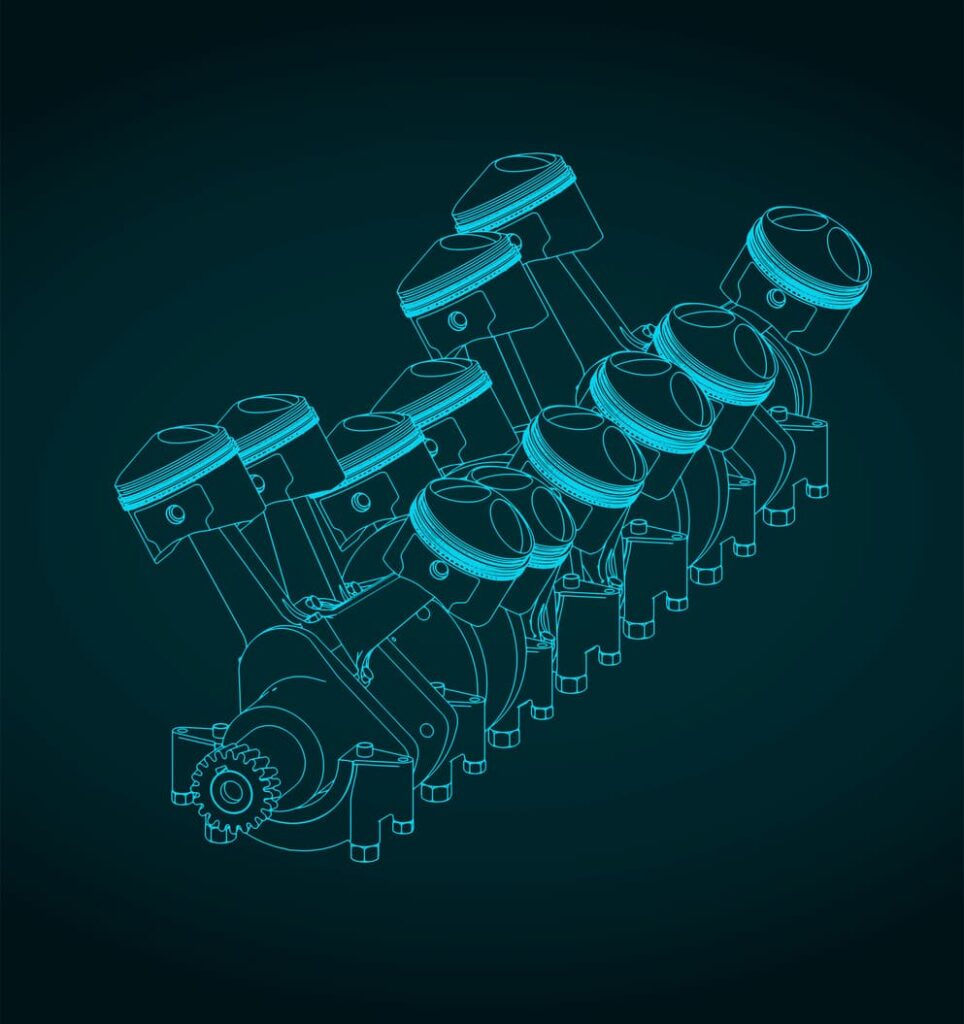

Crankshafts are mechanical components installed in piston-style internal combustion engines. The role of the crankshaft is to convert the repetitive motion of the pistons into a rotational motion. Essentially, the crankshaft is a rotating rod with several crankpins along its length. These crankpins are connected to pistons by connecting rods that force the previously mentioned rotational movement. This redirected motion is then put to use elsewhere within the engine for various purposes.

Crankshafts have similar roles in domestic and industrial applications, but they have one defining difference, scale. As a result, the applications that industrial crankshafts are used in are far more active and intense than other, smaller ones.

Industrial environments expose crankshafts to very high dynamic loads as well as heat. This means they must be manufactured with significant durability, high fatigue and impressive wear resistance. Still, the most durable crankshaft will need to be monitored for wear or repair needs. Repairing this machinery will require engineers with expertise in in-situ crankshaft machining in various industrial environments.

There are different methods of manufacturing the many designs of the industrial crankshaft; here are a few examples.

Flat-plane crankshaft designs are where the journals at the end of the connecting rods are 180° apart. This is a typical design used in many engines. Alternatively, a cross-plane crank requires modules of multiple parts to compensate for the journals and crankshaft counterweights not being symmetrical.

Crankshaft parts manufactured with metal casting are a cost-effective solution for flat-plane crankshafts but, in some cases, are unsuitable for industrial applications due to the potential weaknesses within the liquid metal. Forged crankshaft parts are significantly more robust than cast metal. These forged parts are hammered and twisted to be manipulated whilst remaining solid, which creates a much stronger result. Billet crankshaft parts involve removing unwanted metal to leave just the crankshaft design behind; this allows the metal grain to run parallel along the component length and increase its strength. Whilst this method is effective, it does have increased costs.

With the cast metal's unreliability and the billet process's high costs, most industries choose the reliability of forged crankshafts. As a result, most crankshafts are made from iron, forged steel and steel alloys.

Fully built crankshafts are an assembly of components created separately and then shrink-fitted together. Older engines usually have fully made options, as the crankpins, webs and main journals are forged independently. Bores match the crankpins and journal into the web, and the parts are heated to promote expansion; when they cool, they shrink to a tight fit and prevent slipping.

Welded crankshafts are made of connected webs with crankpins and half the main journal on either side. These welded crankshafts benefit from a continuous metal grain flow that enables thinner designs to handle increased stress.

Semi-built crankshafts are a mixture of the two previous options, with some elements created simultaneously in a single forging. Usually, large two-stroke crosshead crankshafts will be semi-built. This also has the benefit of increasing the strength of the crankshaft.

High-performance engine components like fully forged crankshafts are essential for many industrial machines and need high-quality maintenance to ensure productivity and the safety of your team. A fully forged crankshaft is a crucial component that transforms the pistons' linear motion into the rotational motion that powers the internal wheels.

These crankshafts are created using a forging process. a single piece of high-strength steel is heated and hammered into shape to create a fully forged crankshaft; the results are a crankshaft that is both stronger and more long-lasting as it has a grain structure that is more uniform.

In high-performance industrial machinery, where the crankshaft is subjected to greater stresses than smaller engines, fully forged crankshafts are typically utilised. The forging process makes it possible to create a design that is stronger and lasts longer, lowering the likelihood of failure under the high-stress conditions common for oil rigs, naval marine and transport.

Although fully forged crankshafts are more expensive than cast crankshafts, they are a popular choice for industrial machinery due to the previously mentioned benefits. On-site maintenance is excellent for these crankshafts as much as any other machinery components, as they can be checked at your facility, significantly reducing the downtime of the machine.

Engines with internal crankshafts are used throughout many of the world's essential industries. For example, industries such as utilities, mining and oil all rely on machinery operated by independent engines to help generate power and source raw materials. Renewable energy sources such as wind turbines have industrial crankshafts within their construction to help supply green energy. Marine and transportation use crankshafts in more conventional methods for motive forces.

When offering our onsite machining services, we specialise in being fully aware of the safe working processes required to work safely at these potentially hazardous locations.

Even the highest quality crankshaft will suffer from wear over extended use and eventually need reconditioning. Condition monitoring is common for facility managers who need to monitor their vital machinery. The initial conditioning occurs when the crankshaft is created, and it is assessed to see if it meets the required specifications. Reconditioning is a beneficial process where managers can analyse the condition of the crankshaft and make informed decisions about preventative maintenance or possible replacement.

The unique nature of crankshaft applications makes determining when to conduct checks and reconditioning challenging, but there are a number of factors to consider when planning your scheduled maintenance:

By answering these questions, you can estimate the optimal periods when you should conduct a maintenance check and the potential frequency of repairs. In addition, the engineers we staff at In-Situ Machining Solutions have considerable experience with crankshaft repair. Therefore, we can advise when you should plan a crankshaft reconditioning. For example, if the bearings show increased wear, high oil temperatures or pressures, these are early signs of machine failure, and a reconditioning procedure is highly recommended.

We have decades of experience providing our highly effective in-situ machine repair service for various industries worldwide. One part of that service involves our expert engineers arriving at your facility with unique mobile repair equipment to conduct practical crankshaft repair work. You can view our impressive track record in our various case studies.

We know how vital it is to keep these vital industrial machines working, which is why we will tailor our services to reduce downtime and help keep your operations running productively. We are available 24 hours, 365 days a year, for our client’s emergency needs. Contact us to discuss how we can help maintain your essential machinery.